After completing ISO_ 9008 Recertification DVA is eying for NABL accreditation.

Author Archives: admin

DVA offers the course “Basics of Automotive Engines” in association with Devise Electronics Pvt. Ltd.

DVA has completed ISO_ 9008 Re-certification.

Visit DVA at Auto Expo – Motor Show at Greater Noida to be held from 5 th to 9th Feb. 2016

Fatigue Test 230 lpm , 210 bar Hydraulic power pack 6 Linear actuator (±2 kN to ±250 kN ) Material Test Load Frames (±100 kN& ±250 kN ) 4 Channel controllers Servo-valves Load-cell (10kN to 250kN) Edaq Data Acquisition System (16 Channel)

Thermal Shock Testing DVA has state of the art Thermal shock Testing Machine capable of simulating mild thermal shock from 400 C to 1100 C with capability to add the intermediate temperature steps. We can simulate most critical cycle in this temperature range up to 240 HP diesel engines. Deep thermal shock up to -150 […]

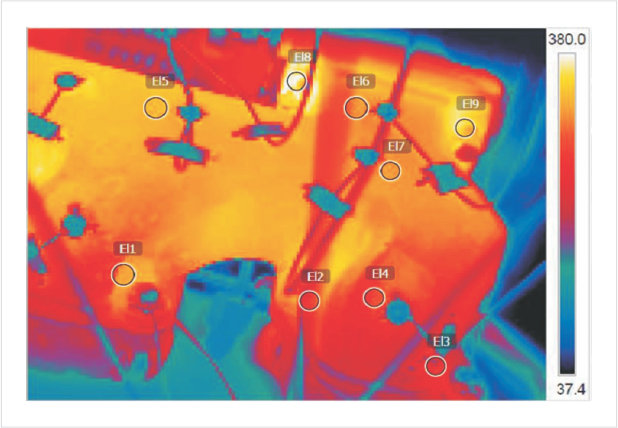

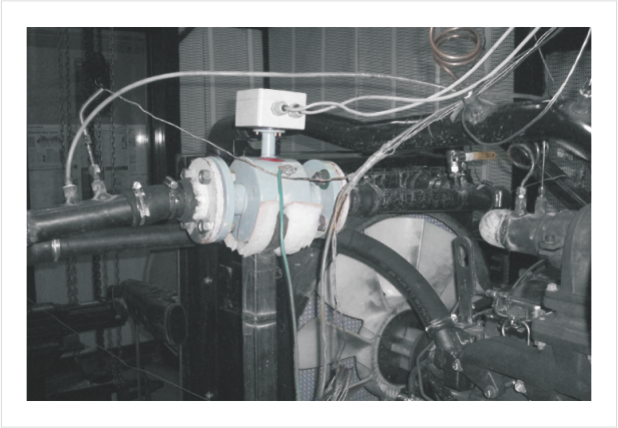

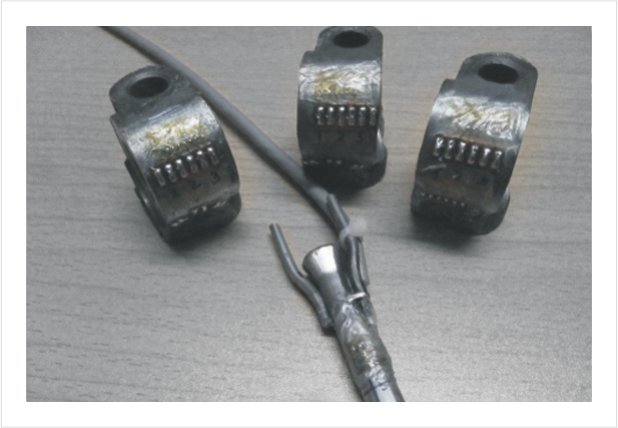

Thermal Mapping of Exhaust Manifold DVA with its specialised experience has developed methodology to map the temperature and gradient across flow path of exhaust manifold. The critical design of exhaust manifold for different material or wall thickness need good prediction of thermal flow. The CAE prediction can be calibrated by welding specially designed temperature sensors […]

Residual Stress Measurement Existing residual stresses from manufacturing process cannot be determined by FEA calculation. The magnitude of residual stresses can be essential and impact the analytical reliability analysis. DVA carries Residual Stress Measurement Test to evaluate the manufacturing process like method of Casting etc., stress pocket and many more things to improve the strength […]

Radiator Efficiency and Optimisation Test The aim of cooling component and its circuitry design is to select and harmonise the Heat balance and optimise the Power it will consume. The vehicle packaging and application matters lot while selecting and designing the cooling circuit. DVA, with its subject expertise & best in class measuring devices such […]

DVA provides strain gauging, measurement and post analysis services. Functional testing such as analytical testing to understand the stress and strain developed in parts under engine fire condition. Feed back on component loads in running conditions. Residual Stress Measurement Evaluation of change in material, process and thereby the cost for reducing product development time.

- 1

- 2