- Cooling Circuit Optimisation

- Radiator Design and Optimisation Test

- Water Pump Efficiency Test

- Water Pump and Oil Pump Efficiency Test

- Thermal Mapping of Exhaust Manifold

- Thermal and Strain Mapping of Liner & Piston

- Alternator & Compressor Loading during Durability Test

- Combustion Studies

- Durability of DPF, SCR System & Urea Dosing Nozzles etc.

- Tilt Rig with Specified Fixturing up to 150 kW Engines

- Metrological Inspection of Power Train Parts and Proto Built

- Teardown Analysis and Report Generation

- Fatigue Test

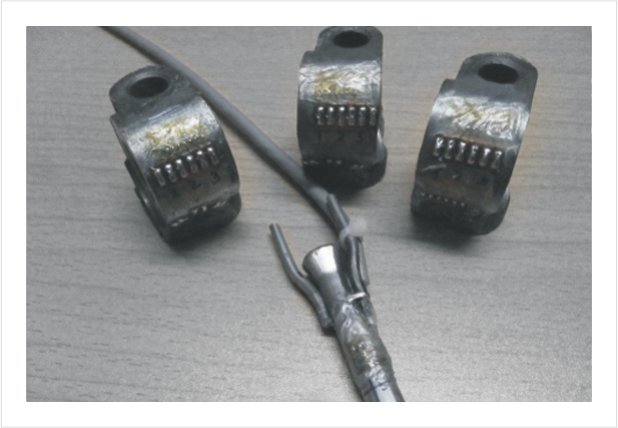

Strain Gauging, Measurement and Post Analysis

DVA provides strain gauging, measurement and post analysis services.

- Functional testing such as analytical testing to understand the stress and strain developed in parts under engine fire condition.

- Feed back on component loads in running conditions.

- Evaluation of change in material, process and thereby the cost for reducing product development time.

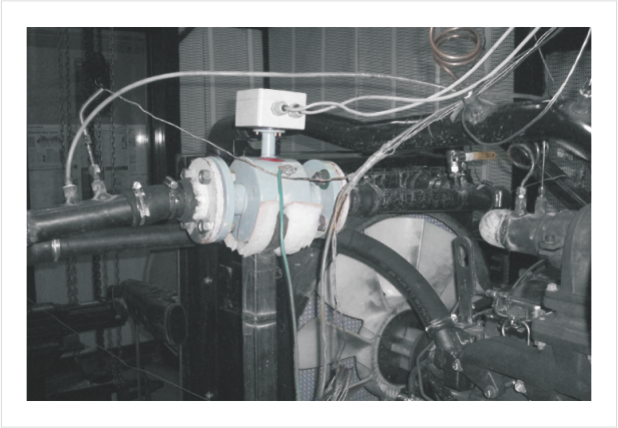

Radiator Efficiency and Optimisation Test

The aim of cooling component and its circuitry design is to select and harmonise the Heat balance and optimise the Power it will consume. The vehicle packaging and application matters lot while selecting and designing the cooling circuit.

DVA, with its subject expertise & best in class measuring devices such as water flow meters, oil flow meters, anemometers analyses the required efficiency which is correct for the application.

Residual Stress Measurement

Existing residual stresses from manufacturing process cannot be determined by FEA calculation. The magnitude of residual stresses can be essential and impact the analytical reliability analysis.

DVA carries Residual Stress Measurement Test to evaluate the manufacturing process like method of Casting etc., stress pocket and many more things to improve the strength of components.

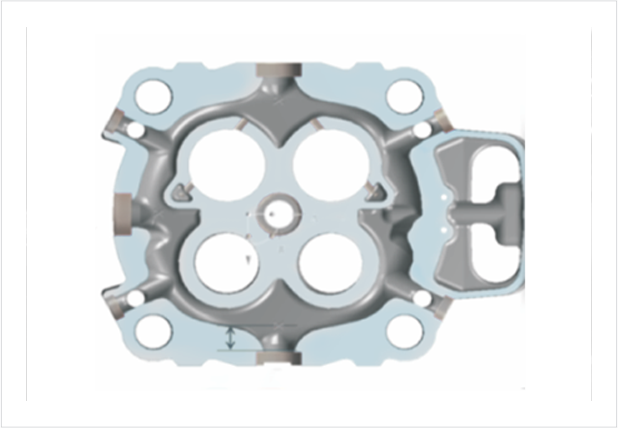

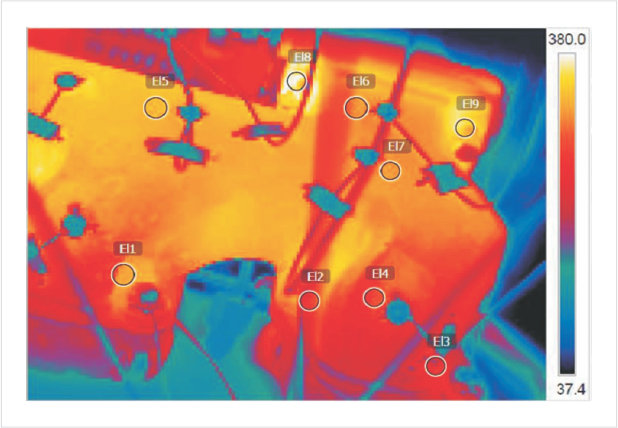

Thermal Mapping of Exhaust Manifold

DVA with its specialised experience has developed methodology to map the temperature and gradient across flow path of exhaust manifold.

The critical design of exhaust manifold for different material or wall thickness need good prediction of thermal flow.

The CAE prediction can be calibrated by welding specially designed temperature sensors at desired location. The combination of strain as well as temperature data will provide insight of thermal restrain ratio to exactly predict the effect due to change in material, shape and wall thickness in the critical design of manifold.

Thermal Shock Testing

DVA has state of the art Thermal shock Testing Machine capable of simulating mild thermal shock from 400 C to 1100 C with capability to add the intermediate temperature steps.

We can simulate most critical cycle in this temperature range up to 240 HP diesel engines.

Deep thermal shock up to -150 C is also possible.

Fatigue Test

- 230 lpm , 210 bar Hydraulic power pack

- 6 Linear actuator (±2 kN to ±250 kN )

- Material Test Load Frames (±100 kN& ±250 kN )

- 4 Channel controllers

- Servo-valves

- Load-cell (10kN to 250kN)

- Edaq Data Acquisition System (16 Channel)

supporting development by working with your vendors

Being your partner, we can work with your suppliers & vendors to speed up your development process. For any component or integrated part like radiator, alternator, cooling circuit etc. - you just give your acceptance criteria, we will work with your supplier to optimise it.

Now supplier change, small Design change in material, process will no more hamper the quality or create risk of failure.

We, as independent agency, can work with your vendor to reduce the gap and time; can provide him our consultancy and testing services to achieve the targets. We will assure our uncompromising reliable data. We can monitor the whole development process and will collectively provide you best in class product you desired.